VA Ann Arbor Healthcare System Research Services

Biomedical Engineering Research Core

Overview

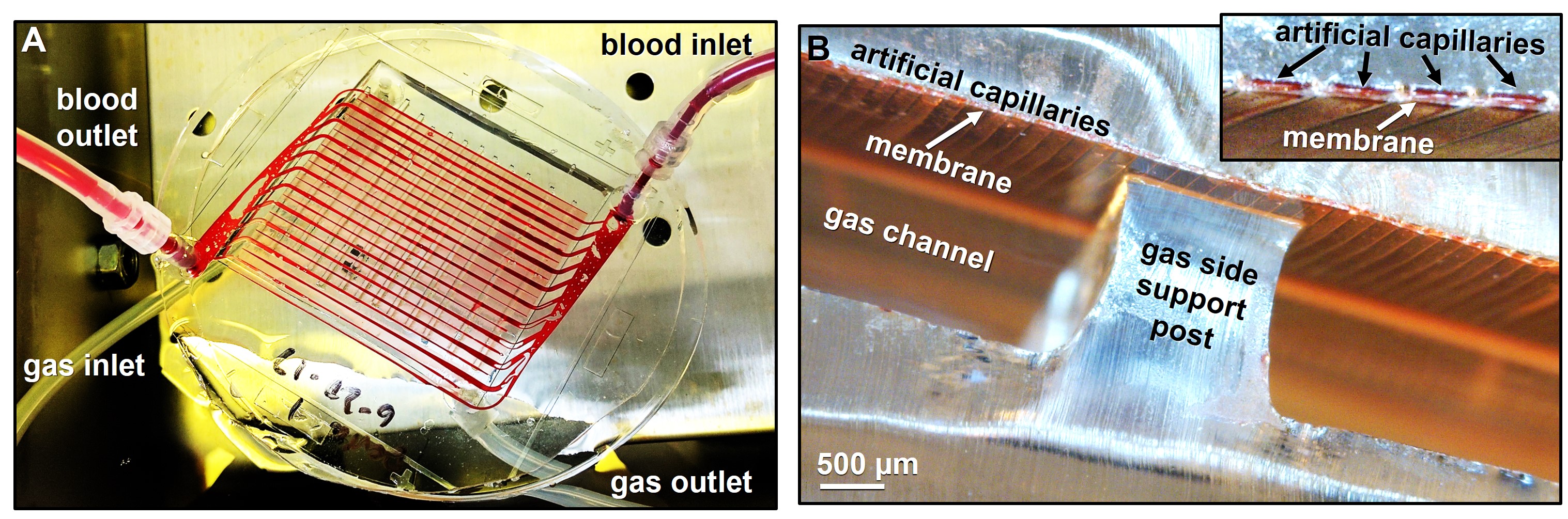

The Biomedical Engineering Research Core at the VA Ann Arbor Healthcare System is comprised of non-clinician engineers and scientists that focus on state-of-the-art engineering research on issues relevant to our Veterans. Expertise within this core includes microfluidics and microsystems, finite element modeling of fludics, 3D printing, artificial lungs design and development, control systems, circuits and electronics, biomaterials, biocompatible surface coatings, neural engineering, intracortical microelectrode design, and central nervous inflammation.

Affiliated Investigators

Joseph Potkay, PhD: microfluidics and microsystems; microfluidic artificial lung design; electrical and computer engineering; artificial lung control systems.

Alex Thompson, PhD: chemical engineering; surface modification/coating; hollow-fiber artificial lung design; finite element modeling of fluidics.

Evon S. Ereifej, PhD: neural engineering, intracortical microelectrode design, nano-architecture, CNS inflammation, biocompatibility, biomaterials

Equipment/Resources

Microfluidic device fabrication: Multi-layer microfluidic devices can be constructed using our hot plates, spin coater (see below), ovens, vacuum chamber, UV exposure unit, and oxygen plasma system (see below).

Microfluidic testing: A set of pumps (peristaltic and syringe), gas flow controllers, and flow and pressure sensor (miniature and clinical) are available for testing microfluidic devices.

Oxygen plasma system: The Nordson March AP-300 Plasma System is a small-size batch-type plasma treatment and cleaning system designed for both the rigorous demands of 24-hour operation in high-volume manufacturing environments and also for use at smaller facilities such as R&D centers, universities, and pilot line production facilities. The AP-300 Plasma System delivers high-quality plasma treatments, unmatched reliability, safety, ease-of-operation, and easy maintenance.

Spin coater: The Specialty Coating Systems G3P-12 Spin Coater accurately applies liquid coating materials, such as photoresists, polyimides, metallo-organics, dopants and silica films, on planar substrates up to 12 inches in diameter.

3D printers: This Core contains two Asiga MAX X27 3D printers with a build volume of 51.8 × 29.2 × 75mm and resolution of 27 × 27 × 1um.

Laser engraver: The Epilog Zing 24 is a high-quality, bench-top laser engraving tool capable of cutting or engraving metals, woods, plastics, rubbers, fabrics, ceramics, and elastomers. It features a 61 x 30.5 cm cutting area, a 30 W CO2 air cooled laser, a positional resolution of 25 µm, and a laser spot size of 75 µm.

Electronics: A data collection and analysis computer, two programmable power supplies, two digital multimeters, a 20 channel data acquisition system, and a solder station are available for electronics projects.

Neurophysiology System: The core has three Tucker Davis Technologies portable Lab Rat Ephys systems to perform electrophysiological recordings. Ability to perform real-time spike sorting and visualization of up to 16 channels. Several biological signal types can be recorded, including single units, LFPs, EEG, and EMG.

Cryostat: Leica CM1520 Cryostat is available for routine histology slicing of various tissue specimens. Capability for section thickness ranging from 2-60 µm.